Lube Level Maintainers

The LM500 maintains oil level on any size engine. It also supports installations that require a three-wire, snap-action switch.

- Test feature allows test of float and switch

- Direct mount capable

- Eliminates under/overfill due to human error

- See oil level and condition without shutting down

- Simple installation

- Automatically maintains lube level

- Positive sealing thumb valve

Not intended for use with fuel

FW Murphy Production Controls offers support for all our products. If you are unable to find the product that you need, please call us at 918-957-1000.

The LM500’s form C (three-wire) contact allows a controller/annunciator to be wired as a closed loop system, resulting in a reliable fault-sensitive circuit. Refer to LM500 Series Flow Rate Chart for application data.

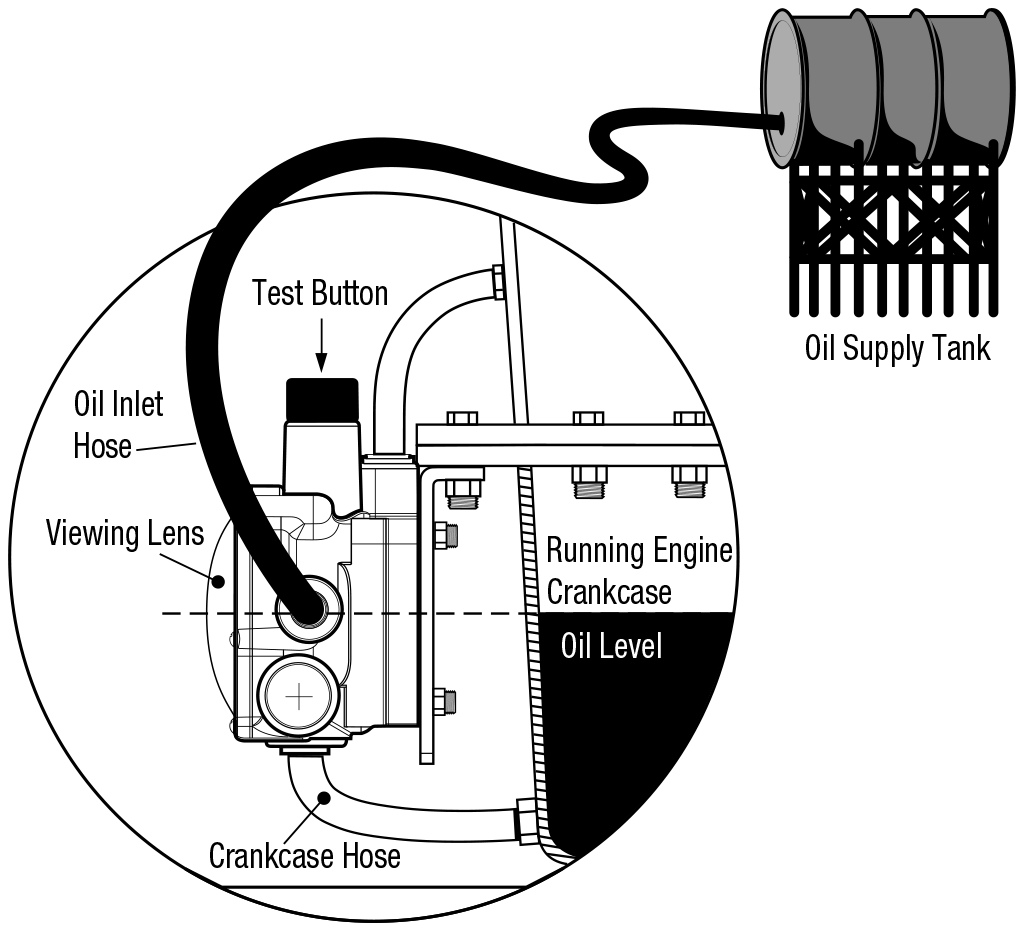

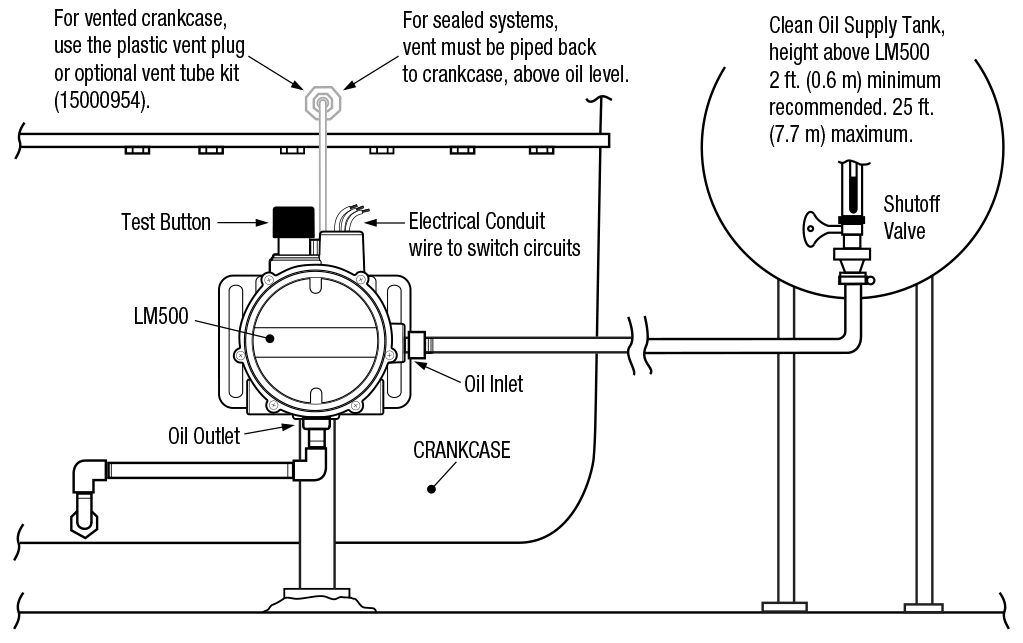

The FW Murphy LM500-TF Oil Level Maintainer includes a test feature that confirms both the float and switch are operating correctly with a single press of the test button. The LM500 series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running oil level, it will replenish oil as it is used. The low-level switch will alarm and/or shut down the equipment, if supply oil is lost and the equipment continues to use oil.

As crankcase oil level drops, the LM500 float also drops and opens the thumb valve. This allows oil to flow from the supply tank through the LM500 and into the crankcase. When proper level is achieved in the crankcase, the LM500 float rises causing the thumb valve to close off further oil flow.

The simple and unique thumb valve is non-clogging and provides a positive, leak-free seal.

If the clean oil supply is depleted and oil level continues to fall, the low-level switch will operate an alarm or equipment shutdown.

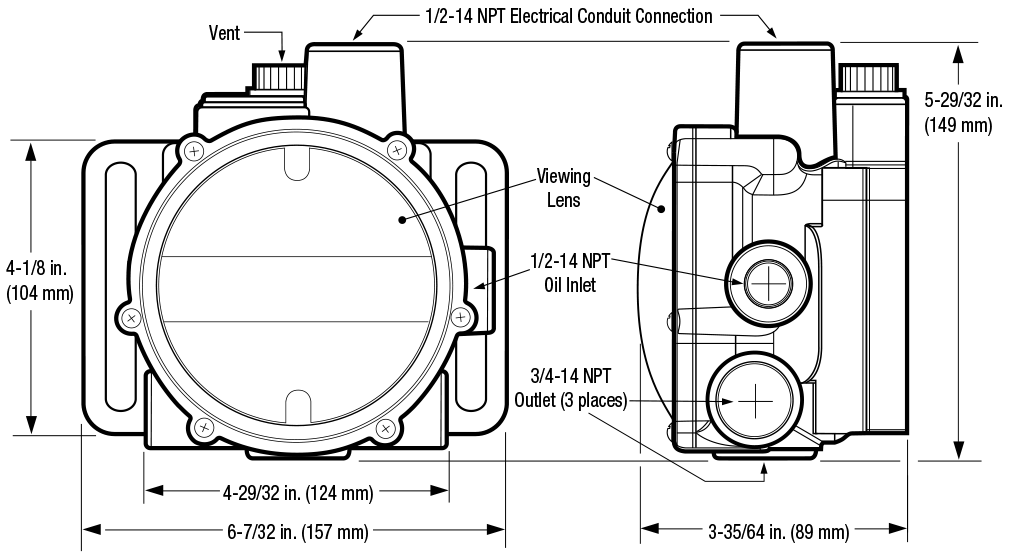

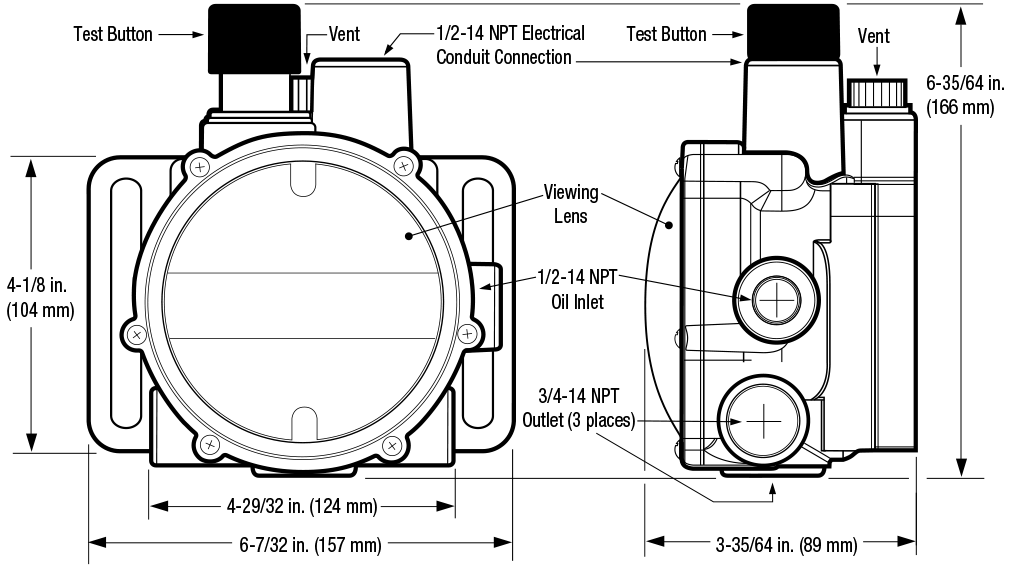

- Crankcase Balance Vent Connection: 1/2 NPTF (top)

- Inlet Connection: 1/2 NPTF removable screen (side)

- Outlet Connection: One connected, two not used (plugged)

- 2 x 3/4 NPTF (side)

- 1 x 3/4 NPTF (bottom)

- Thumb Valve Material: Viton

- Snap-switch: SPDT rating 10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC

- Wire leads: 18 AWG x 14 in. ± 2 in. (355 mm) length

- Conduit Connection: 1/2 inch conduit (female, top)

- Case: Die cast aluminum

- Lens: Clear frog eye non-staining, high impact, high temperature polycarbonate; UV and heat stabilized

- Dial: High visibility white background with solid green band for normal level indication

- Maximum Inlet Pressure: 9.50 psi/25 ft. oil (head pressure)

- Maximum Case Pressure: 15 psi (103 kPa)

- Maximum Differential: 2 in. (51 mm) between running and stopped

- Maximum Ambient Temperature: 250°F (121°C)

- Float: 304 Stainless Steel

- Flow Rates: Refer to LM500 Series Flow Rates chart for application data

- Dimensions: Overall 6-9/16 inch tall x 6-3/16 inch wide x 3-1/2 inch deep

For exact dimensions, refer to document 00-02-0729 LM500 Installation Instructions - LM500/LM500-TF Shipping Dimensions: 9.5 (W) x 7.5 (D) x 11 in. (H) (241.3 (W) x 190 (D) x 279.4 mm (H))

- LM500/LM500-TF Shipping Weight: 3 lbs. 7 oz (1.57 kg)

Dimensions: LM500

Dimensions: LM500-TF

Typical Universal Mount LM500/LM500-TF

Typical Pipe Mount LM500/LM500-TF

For more information about this product, you can download the related literature here:

Sales Bulletin (1010627; revision date: 02/2025)

Installation Instructions LM500/LM500-TF (00-02-0729; revision date: 02/2025)

Bubble Lens Assembly Instruction (00-02-0785; revision date: 7/2014)

Installation Instructions LM500-TF-ATEX (00-02-0745; revision date: 03/2020)